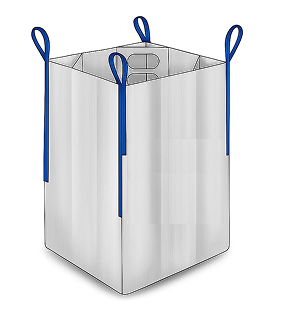

I. The Baffle Mechanism

Internal Panels

The baffles (four rigid, vertical fabric panels) are sewn within the bag, and they connect the four side walls. These baffles have carefully designed peaks that can enable the material to flow from the center to the corners and sides.

Anti-Bulging Technology

When the bag is filled, the internal baffles oppose the hydrostatic pressure and therefore the walls do not bow out. This will make the bag preserve its approximate square top-to-bottom footprint.

Structural Integrity

The vertical composition of the bag is strengthened by the baffles, which enable the Q-Bag to be incredibly stable when stacked in multiple layers, as well as very unlikely to topple over even when piled with heavy, dense materials.

II. Maximizing Volume and Freight Savings

The major advantage of the Baffle Bag is that it gives an optimum Cubic Utilization of shipping containers and trailers.

Freight Optimization

Baffle Bags minimize the air voids in between bags by filling the corners. Clients regularly meet load capacity up to 30 per cent higher per shipment than the standard bags, which is vital in saving money on both international FIBC Exporters and freight expenses.

Warehouse Density

The square shape is perfect and is stacked up with no gap. This enables it to store a large amount of data in a small space, which minimizes the physical capacity in warehouses and storage yards.