The Internal Safety Net

It is an ingenious safety element, which is titanically incorporated into the very cloth. Our Type C bags are not electrical insulators, like regular plastic bags, but are woven to an internal, fine network of special conductive threads. These running threads pass all over the body of the bag and, in effect, become some sort of invisibility net that draws and influences the electrical charge. Such construction makes sure that the bag does not contain a life-threatening amount of electromagnetic charges. The threads instead offer a quick, secure pathway in which the charge is taken off the bag surface as fast as it is formed, as opposed to piling up, thus causing a spark.

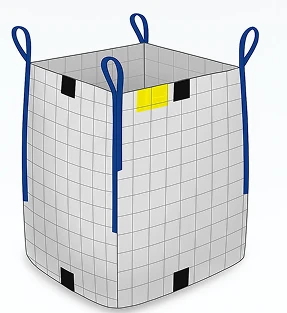

The Mandatory Grounding Connection

The next important, and last step towards the complete, guaranteed safety of the Type C bag is simply a connection to the earth, or grounding it. Each certified bag is produced with visible and heavy-duty safety connection tabs attached to the bag body. These tabs should be well fixed during the filling and discharge stage through a special-purpose cable to a certified ground in your plant. This is a small, yet important, operation, which completes the circuit of electricity required, and then permits the charge that has been built up by the internal threads to pass into the ground harmlessly. Without this basic grounding process being done correctly and properly, the bag will fail to carry out its safety role, but it still carries the concealed danger of a normal, uncertified container of a potential fire.