Vented Fabric Panels

The main source of the ventilation is the weave of the fabric. The bags are made of woven PP fabric panels that are made with bigger gaps or looser mesh designs. This construction can pass freely through air and moisture vapor, and this encourages the removal of the leftover moisture and avoids the damp, stuffy environment that causes spoilage.

Integrated Air Stripes

In some applications, the bags are made of a blend of regular woven PP cloth to provide strength and ventilated air stripes at strategic locations. They are vertical stripes of very porous and open-mesh fabric stitched into the sides of the bag. This offers dedicated openings of air entering and leaving the structure, which offers a higher level of protection and does not compromise the load-bearing of the primary structural panels.

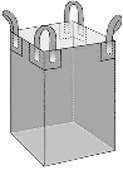

Structural Integrity

The Ventilated Bag maintains the required strength, although it provides maximum airflow. Such bags are usually constructed based on the Circular/Tubular or reinforced panel design principles that make the bags have a strong Safe Working Load (SWL) of their intended contents (e.g., 1,000 kg of potatoes) and be stackable and forklift-handled.