Dedicated Cleanroom Production

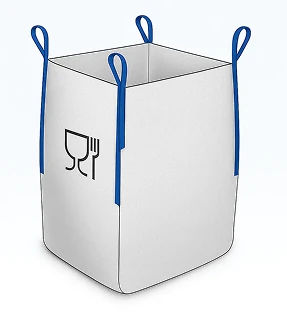

We manufacture all our Food-Grade bags in specific cleanroom plants in Gujarat. These are under strict measures, such as positive air pressure systems to constantly remove possible airborne particles, and mandatory hygiene and gowning measures for all staff. This highly controlled and stringent setting keeps the fabric and stitching of the bag untouched since the first cut up to the last inspection.

Virgin Resin and Contamination Control

The woven fabric is made using 100% pure virgin polypropylene resin that is in conformity with all the food-contact regulations. Use of recycled or reprocessed materials is totally forbidden. Moreover, we also use special methods, such as metal checks and close internal vacuuming at the end of the packing process, to make sure that there are no foreign objects, in other words, broken needles, threads, or dust particles, in the end PP woven bag. Such dedication to hygiene is what qualifies us as a reliable partner of food bag manufacturers around the world.