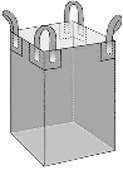

The Continuous 'U' Foundation

The key characteristic of this bag is the single continuous piece of woven polypropylene (PP) material that constitutes the bottom of the bag and extends upwards to form 2 opposing side walls.

Minimized Stress Points

The base seams in most of the bag constructions are subjected to the vertical load. With the U section cut out of a single continuous piece, we are able to remove the two large horizontal seams at the base corners. The entire bottom fabric carries the load of the design, hence making the possibility of failure of the seams under tension or force very minimal.

Vertical Load Transfer

The woven fabric is composed of warp (vertical) yarns that flow uninterrupted in the lifting point, down the side, over the base, and up the opposite side. The same structure makes sure that the vertical forces are absorbed and controlled by the body of the fabric as a whole and not by localized stitching.

The Two-Panel Infill and Reinforcement

There are two additional bag sides that are closed with a separate panel. This is the place where Lakhotia Polyfab uses special methods:

Custom Seam Finishes

Our side seams are done in an advanced chain stitching with proprietary sift-proofing. With fine powders, particularly fines (e.g., pigments, flour), we incorporate felt gaskets or heavy-weight filler cord to the seam line to guarantee complete containment of the powder, so that it does not leak into the powder, resulting in contamination or loss of powder.

Fabric Denier Optimization

U-Panel bags tend to be used with materials that have a large bulk density (pounds per cubic foot). To maximize the tear resistance and tensile strength on the entire load-bearing surface, we specify a heavier GSM (grams per square meter) and a denier that is heavier (thicker and stronger individual threads).