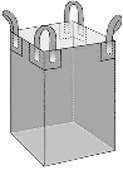

Circular / Tubular Jumbo Bags

Cost-Effective, Seamless Containment for Free-Flowing Commodities

Circular or Tubular Jumbo Bag is an efficient, economical, and durable packing solution that is especially popular to use with powdery and granular substances and agricultural goods that have free flow.

This design is produced on a rotating base and thus has a better structural integrity since all vertical seams that are present with panel bags are eradicated, hence making it a good design in reducing sift leaks and maximizing the production rate.