Superior Barrier and Durability

High-Definition Graphics

The quality of printing is the key difference maker. BOPP film is compatible with Reverse Rotogravure Printing (printing on the reverse side of the film) with as many as 8 or 10 colors in a photographic, high-definition finish. This degree of graphic quality can not be attained on normal woven fabric. It allows branding intricacy, expressive logos, specifications, and a high-impact retail presence, and it will make the Jumbo Bag more than a container: it will be a marketing tool.

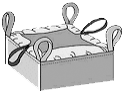

Single-Operator Handling

The overall functional advantage is that only one forklift operator can enter the tunnels, grab the bag, and move it without the operator leaving the cab and without any assistance to get the loops to the right place. This feature is essential to high-throughput logistics centers, eliminating the cost of labor and dramatically accelerating the speed of the loading and unloading processes. This becomes particularly beneficial to Single-Trip FIBC Bags, where speed is the key.

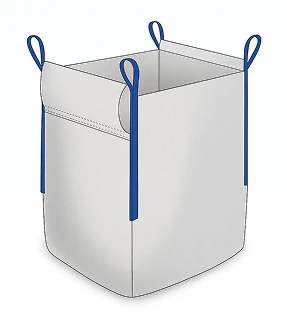

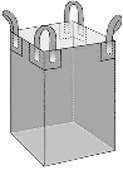

Structural Integrity and Stability

Tunnel Bags are commonly erected on the strong base of U-Panel Jumbo Bags or Four-Panel Jumbo Bags in order to maintain the highest degree of structural stability. This design ensures that the bag is able to keep its cubic shape to stack high and densely, as well as have expedited handling of the tunnel system. The load-bearing capacity and the Safe Working Load (SWL) are certified to the same level as the traditional loop bags.