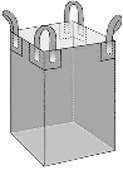

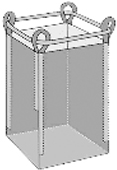

Component-Based Strength

The sides of the bag are made with four separate pieces of woven polypropylene fabric, which have been carefully sewn to a fifth and exclusive square base panel. This gives us the opportunity to utilize heavier GSM (Grams per Square Meter) cloth and a better tensile strength thread in all five panels without affecting the shape of the bag.

Maximum Shape Retention

Its strength is inconsistent, ironic with the many seams, eight seams to be precise. Every seam forms a stiff column or corner when the bag is full, which means that the bag must keep its precise square footprint. This helps in the avoidance of the belly or bulge that other types of bags have, which is very important in the stuffing of the container, as well as the high-density warehouse storage, where every centimeter matters.

Load Distribution and Safety

With a Four-Panel bag, the load is evenly spread over five fabric-covered surfaces, and this means that stress points are predictable and work well at high Safe Working Loads (SWL). This construction is commonly required on Multi-Trip FIBC Bags (6:1 and 8:1 SF) since the reinforcement that is individual in the panel is very good for the durability of the item against repeated wear and tear.