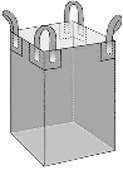

Form-Fit Liners (FFL)

These are the most advanced liners, which fit the exact size and shape of the interior of the outer Jumbo Bag (i.e., Four-Panel or Baffle Bags). Form Fit Liners are attached to the structure of the outer bag on the top, bottom, and corners. This ensures:

Zero Movement

The liner remains fixed on the filling and discharge, and it does not tear or bunch to cause disruption in the flow of the product.

Maximized Volume

The liner will fill all corners, hence making the bag take the shape of a cube, the use of freight and warehouse space is maximized.