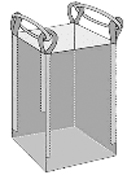

Superior Fabric Specification

A Heavy-Duty bag is based on the principle of woven polypropylene (PP). We use a much heavier Grams per Square Meter (GSM) cloth and a denser (thicker) thread in the weave. This thick, sturdy material is ultra-tear and puncture, which is essential in situations of holding sharp or abrasive substances such as heavy aggregates and dense mineral ores. The stronger fabric density assures that the bag will have its certified strength during constant stress and extreme conditions.

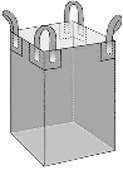

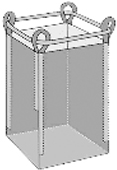

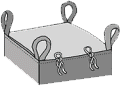

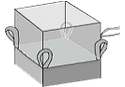

Reinforced Lifting Systems

Lifting loops are the critical element of failure on any FIBC, and they have to be designed to withstand the enormous forces produced by a weight of 2 tonnes. We design extra-wide and high-tenacity lifting webbing, and use special reinforcement patches and sewing designs at the loop-to-body connection point. These bags are most commonly framed on the inherently robust U-Panel Jumbo Bags or Four-Panel Jumbo Bags, whose corner seams form the required support structure to evenly spread the extreme vertical load out over the entire base.

Enhanced Safety Factor

A Multi-Trip bag will be reuse-oriented, whereas a Heavy-Duty bag is mass-oriented. These bags are also frequently rated to maximum possible safety measures, such as an 8:1 Safety Factor (SF), which offers certified assurance that the bag can sustain eight times its rated SWL during experiments, which provides an unmatched level of security for both the personnel and the cargo.