Gravity-Assisted Flow Dynamics

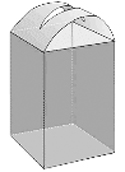

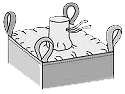

The most important thing about the Conical bag is its interior design. The cloth walls change gradually, taking the shape of the square or circular shape of the body to a clear-cut cone at the base. Such an inclination forms a continuous push on the material that is just above the discharge hole. This constant movement or channeling will not allow the material to settle, compact, and create a bridge or arch that will obstruct the flow.

Stress Management and Sift Resistance

The tapering base is made by sophisticated stitching and pattern cutting so that it structurally holds its shape even with the complex angles. We reinforce the joints at the point of taper and use specialized and dense weaving to keep the seams together. This is such that a base encourages flow but is still fully containment-qualified with the ability to sustain heavy loads without damaging the overall Safe Working Load (SWL).

Optimizing Cohesive Powders

Conical FIBC is targeting cohesive powders - substances that lack adhesiveness, i.e., are inclined to stick on surfaces and build up. The sharp angle kept between the bag wall and the discharge point means that the friction of the product against the wall of the bag is reduced to a minimum, meaning that the products will flow continuously with a smooth flow until the bag has emptied.